3K in one mould

3K in one mould

3K in one mould.

At the tool design stage we already keep in mind to guarantee optimized and reliable production.

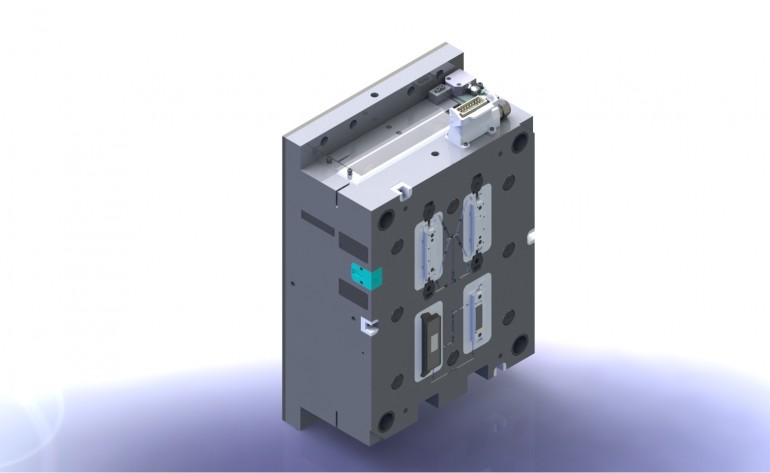

The project involved design and machining of injection tool. The moulding comprised of three thermoplastic components – TPE, PC and PMMA – all of them injected into one tool. Transfer of parts to overmoulding cavities war realized by robot gripper. Solution provided by KarT outplaced former, less effective production process. Two separate tools (one of them with rotary moving half) were used thus far – we managed same product with one tool. No rotary action was needed. The production process was shortened what influenced significantly moulding quality and scrap-rate. No additional logistic and stock-keeping activities were needed for production.

This state-of-the-art tool construction is designed to meet current injection molding mass production standards. Forming parts of the tool were made of hardened steel. Injection of PMMA and TPE components is realized by two additional injection units that are fixed to moving half on operator and non-operator side of the tool.

About us

Shortcuts

Kontakt