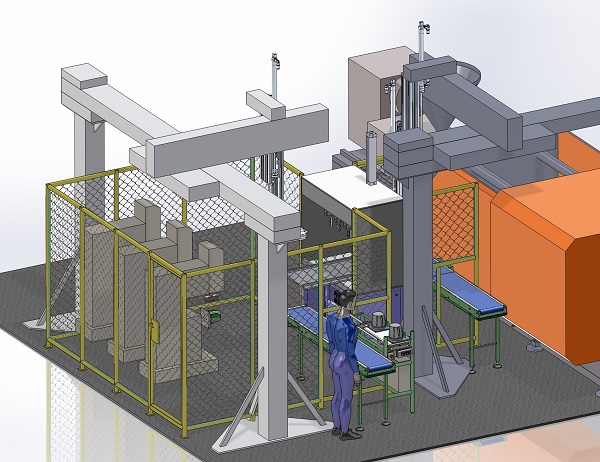

Automatic kettle inscription line

Automatic kettle inscription line

Automatic kettle inscription line is used for corona treatment and inscribing on the kettle body in automatic course.

The line consists of:

1. Demag Ergotech injection moulding machine with an ATM Automation robot.

2. Tantec corona treatment system, modified to allow three-position work.

The corona treatment system consists of a covered supporting frame made of steel, with the controlling system located inside. Corona treatment system body made of aluminium plates is placed on the frame. Inside the body, there is a plate with the guide rails, along which the cart with the plugs moves, driven by two pneumatic servo-motors. The head of to the corona treatment systems, equipped with electrodes, moves on the vertical plane above the plugs.

Modifying the corona treatment system to achieve three-position work consisted of:

– adding the plate with the guide rails upon which the intermediate cart and the plug cart is placed.

– creating a new plate for the head to increase the spacing of the head guide rails,

– adjusting the electrodes on the corona treatment system head,

– modification of the back body plate and changing the position of the head servo-motor

3. Double-sided rotating gripper and manual feeder with control system.

The gripper is built out of four main elements: robot fitting system, rotation system, grippers for the body of the kettle and mounting elements. The manual feeder consists of a steel supporting frame with a plastic platform upon which the plug cart moves on a rail. The cart is driven by the rodless actuator located under the covers.

4. Guarding of the work area.

The guarding has been constructed out of commercial elements (posts, net panels, tilting and bracket door sets, locks). Control boxes which enable bar unlocking and door opening are located on the net panels by the door. A signal light tower is mounted on the post by the corona treatment system. The net panels are mounted on the posts with the use of latches. A special key, delivered with the guarding, is used to disassemble the panels.

5. APEX SC2000D Robot.

6. Three printers which are installed on the common supporting frame.

7. Belt conveyors.

About us

Shortcuts

Kontakt