Magnetic conveyor

Magnetic conveyor

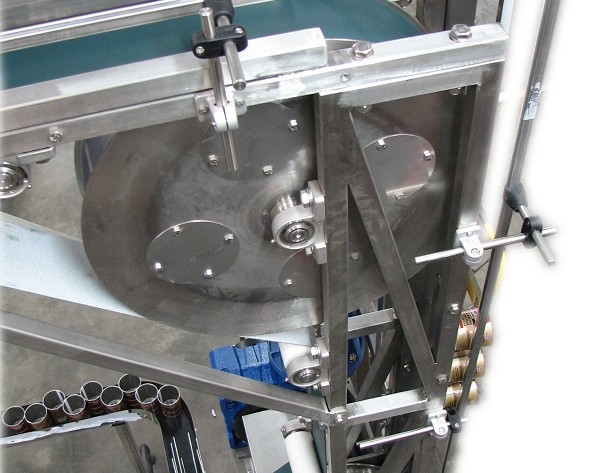

Magnetic conveyor is used to transport empty cans of max. Ø73 diameter, 95 mm height and max 0.5 kg weight. It is a structure made of an acid-resistant steel with elements made of plastics, equipped with electrical system powered by 400VAC. The electrical system is located in a separate power supply and control box. The conveyor is made of the following elements:

- input,

- output,

- top connector,

- diagonal connectors.

Both input and output are made of latticed structure anchored to the ground. The conveyor belt moves on the conveyor. Reduction gear with the motor is mounted in the output. Belt tensioners are placed on the diagonal connectors. Magnetic force on the vertical splines is achieved through the magnetic holders. Propulsion from the motor reducer is transferred through the clutch onto the drive drum. Movement of the belt is conveyed through the non-drive drums and internal rollers. The drive drum is placed in the housings of UCP209 bearings, while the non-drive drums and internal rollers in UCP204 bearings.

Magnetic conveyor – technical data:

- Length ~ 5500 mm

- Width ~ 800 mm

- Height ~ 3180 mm

- Conveyor belt – width: 110mm, length: 19 505mm; connection EM;

- Speed of tape (regulated) – max. 90 rot/min – ~14m/min

- Gear motor CM130 i=100 1,5kW 400V 900 rot/min

- Inverter V1000 1,5kW

- Dimameter of drive wheel Ø500mm

- Power supply 3x400V AC 50Hz 4A

- Weight ~515kg

About us

Shortcuts

Kontakt