Cigarette filter cutting line

- Home

- Production lines

- Cigarette filter cutting line

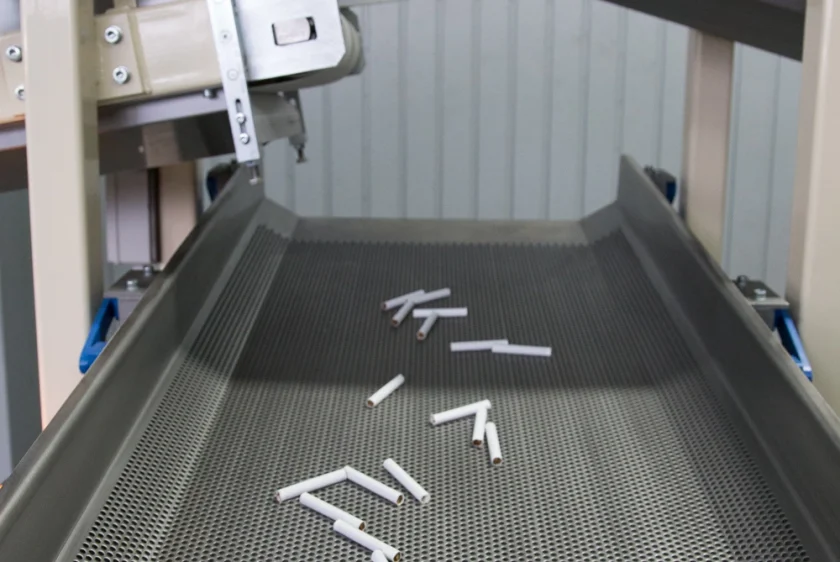

It consists of a series of devices connected into a single line. The process involves recovering tobacco from cigarette packs by cutting the pack at the point where the tobacco meets the filter, then separating the filter section from the tobacco section, shaking out the contents into a conveyor, and sorting the tobacco, filters, and packaging into three separate containers. The recovered tobacco in paper wraps is then passed on for further processing in the plant.

The cigarette filter cutting line consists of: a pack pusher with a vision system, a conveyor belt, a vertical band saw, a turner, a vibrating conveyor, a belt conveyor, and a final sieve.

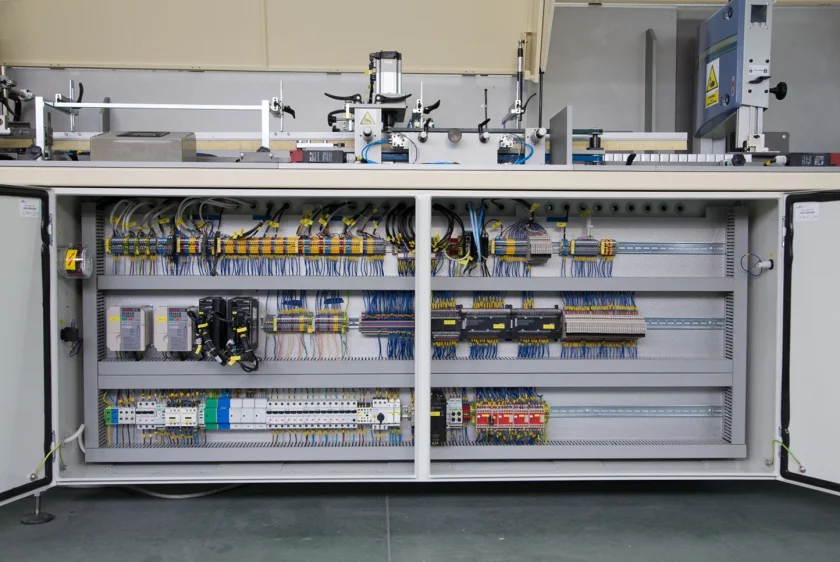

The machine is designed as a modular structure. Each module is built on steel load-bearing frames with hinged covers for the working parts. It is equipped with an electrical installation powered from a 3×400 V AC network and a pneumatic system powered by compressed air at 6 bar pressure. The line features a single integrated control system.

The operation of the line involves loading a cassette filled with packs arranged in rows. The entire row of packs is cyclically pushed into the working area by a pusher. A key element is verifying that all the packs are arranged in the same way, i.e., with the filters oriented in the same direction, to prevent filters from entering the final tobacco container. The pack orientation check system is implemented with two FQ2 vision sensors. Detection of a wrongly oriented pack in the line causes the pusher to stop and the pack is ejected using a movable pin driven by a pneumatic linear actuator. After removing the incorrectly oriented pack, the pusher continues its work, pushing the entire row further into the buffer area, where the packs are transferred to a belt conveyor that moves the product steadily to the cutting chamber. There, the packs are cut using a vertical band saw. The section of the pack with filters is pushed into the appropriate waste container, while the tobacco section is flipped with the opening facing down, and its contents are shaken out from the packaging on a vibrating conveyor into a belt conveyor. The tobacco in paper wraps is transported to the container and sent for further processing in the plant, while the empty packaging is directed to the next container as waste.