Tooling and injection molding

- Home

- Tooling and injection molding

- Offer

- Tooling and injection molding

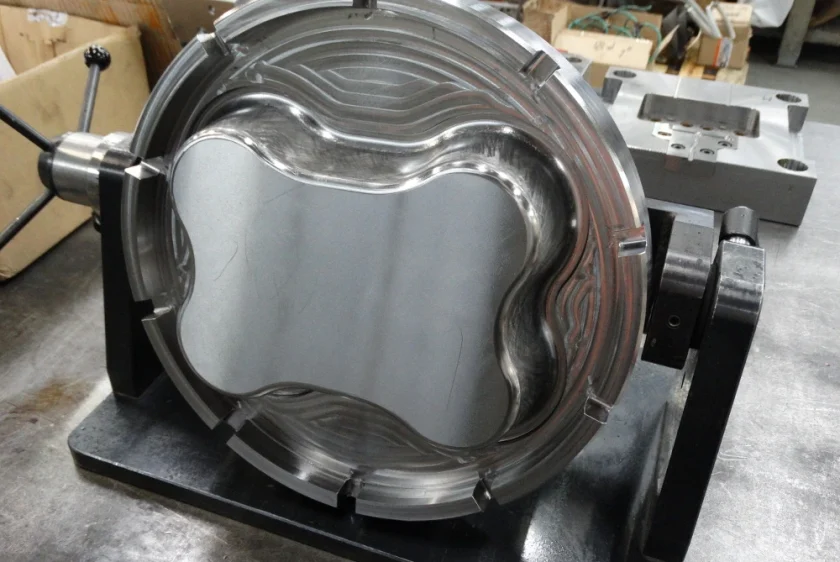

Our professional tooling facility is equipped with CNC machining centers, numerical lathes, and an automated injection molding park, enabling us to deliver products characterized by precision and the highest quality. Our molds and the components produced from them are used in various industries, including medical, sanitary, automotive, food, furniture, and cosmetics.

We base our work on the documentation provided by the client for the finished product, or we develop the product together with them to meet their expectations. After a thorough analysis and definition of the assumptions, we prepare the design documentation—CAD/CAM design, 3D models, and technological documentation. We then pass this on to production, conducting trial injections on the produced mold. All of this takes place in our facility, allowing us to maintain control over every stage of the process, enabling us to quickly respond to any changes or modifications, and to deliver a product that meets the client’s requirements.

You don’t need to have your own injection molding facility; we will design and manufacture the mold, and then produce your details on-site, checking their quality, packaging them according to your specifications, and delivering them to the address you specify. The comprehensiveness of our service is one of the features that distinguishes us and saves you time.

wykonamy formę, a następnie na miejscu wyprodukujemy Twoje detale, sprawdzimy ich jakość, zapakujemy według Twoich wytycznych i dostarczymy pod wskazany przez Ciebie adres. Kompleksowość usługi jest jedną z cech, która nas wyróżnia i oszczędza Twój czas.

Our Capabilities

Offer

- Design and manufacture of injection molds (2K, 3K, IML, overmolding) – up to 5 tons.

- Conducting mold trials on Arburg machines from 50 to 550 tons, with the possibility of subsequent serial production

- Production of plastic components using injection molding (including multi-component injection) using our own molds or those provided by the client.

- Design and production of cutting and stamping tools.

- Production of prototype tools.

- Modification of injection molds.

- Inspection, repair, and regeneration of molds and tools.

Machine park

- ALLROUNDER 720 S 3000-1300 Golden Edition hydraulic injection molding machine.

- ALLROUNDER 420 C Golden Edition injection molding machine.

- Allrounder 370 S 500 - 70 injection molding machine.

- ALLROUNDER 630 S 2500-800 injection molding machine.

- 5-axis machining center Mikron Mill P 800U.

- Deep electro-erosion center FORM P 600.

- Wire electro-erosion center CUT P 550.

- Milling center MIKRON VCE 1600 Pro.

- Machining center Mikron MILL S 500.

- Horizontal lathe center Doosan Puma 2600 LY II.

- CNC grinder BUB E 40 1500.

- Wire electro-erosion machine ROBOFILL 380.

- Deep electro-erosion machine ROBOFORM 400.

- Laser marking machine ACI Ventus 20W.

- Laser welding machine EVO MOBILE 200 Mobil Short.