Cigarette filter cutter line

Cigarette filter cutter line

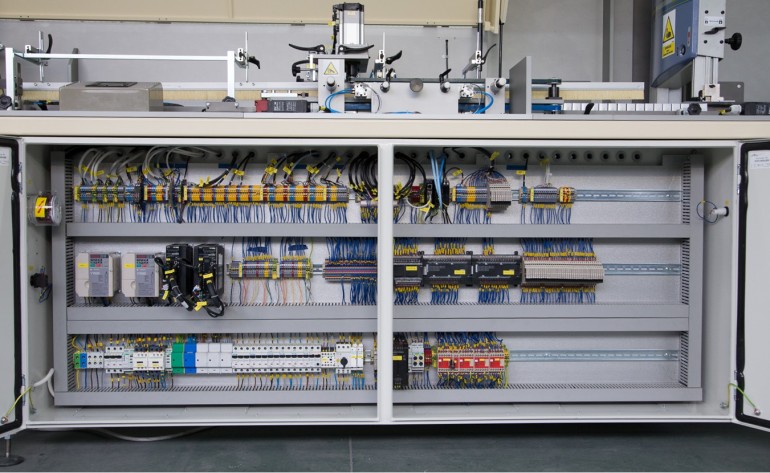

Cigarette filter cutter line has been constructed and launched in its entirety by KarT Sp. z o.o., including the design of the mechanical structure, drawing up the controlling conception, designing and installing of the electrical system, construction of the mechanical parts, as well as assembly and on-site start-up.

Cigarette filter cutter line consists of a series of machines connected into one line. The goal of the process is to retrieve tobacco from cigarette packets. It consists of cutting through the cigarette pack at the point of contact between the tobacco and the filter, and then separating the part with filters from the part with tobacco, shaking out the content of the packaging onto the conveyor and dividing them into three separate containers for tobacco, filters and packets. The retrieved tobacco, wrapped in paper, is conveyed for subsequent processing in the factory. The KarT sp. z o.o Cigarette filter cutter line consists of: side pusher with vision system, belt conveyor, vertical band saw machine, tipping machine, vibrating conveyor, belt conveyor, final sieving machine.

The machine has a skid frame design. Respective modules are built upon a steel supporting frame with adjustable covers of the working parts. It is equipped with 3×400 VAC mains powered electrical installation and pneumatic installation powered with compressed air of 6 bar pressure. The line has one integrated control system based on the Omron’s components.

The operation of the line boils down to loading in a cartridge filled with packets arranged in rows. The whole row of packets is pushed cyclically to the working area with the side pusher. The key element of the process is to check if all the packets are arranged in the same way, that is with filters facing the same direction to prevent the filters from getting into the final tobacco container. The system checking the packet orientation is based on two FQ2 vision sensors. Detection of the incorrectly arranged packets leads to the pusher ceasing to operate and pushing the packet out with a moving shaft powered with a linear pneumatic servo-motor. After removing the incorrectly oriented packet, the side pusher continues its operation, pushing the whole row further back to the buffer zone, from where they are moved to the band conveyor, which moves the product to the cutting chamber in a uniform motion. There, the packets are cut on a vertical band saw machine. The part of the packet that contains filters is moved further to a proper discards container, while the part with the tobacco is flipped hole downwards and its content shaken out from the packets in the vibrating conveyor onto the band conveyor. Tobacco wrapped in paper, intended for subsequent processing, is transported to the container, while the empty packets end up in another container, in order to be discarded.

About us

Shortcuts

Kontakt